Last weekend I flipped the boat. I used a hand winch to pull from one side and a heavy duty ratchet to give slack on the other.

Preparing to flip. This side is the “pull” side; a hand-winch, shackle and towing straps. Two straps run athwart / across the boat, to the far side gunwale for pulling leverage.

The hand winch was between a towing strap that I double wrapped around a large tree trunk, and two other straps shackled to the winch hook. These two straps were clamped to the far side of the boat so that when I reeled in the winch, the far side of the boat lifted up while the near side flip frames dug into the driveway. The theory was that I slowly pulled in and gave way so that the boat was secure at all times.

I used my workbench as a stopgap to rest the boat on after the initial lift, just in case I had to adjust something. I removed the casters so that I could use it horizontally or vertically. Turns out I needed to make adjustments, so it helped.

Mid-flip. Pulling on one side, giving slack on the other side. Everything depends on the strength of the frames and carriage bolts at this point – they are what’s making contact with the driveway.

The hand-winch and straps worked very well. The winch has 6′ of reel length, so it was manageable to pull in, slide in the workbench, give out new slack on the winch, remove the workbench….and so on and so forth. I took it in small steps though.

Post flip. My helper was very excited to see the inside!

The ratchet giving slack failed with about 2′ of flip left. I had it attached to a bar clamp that I THOUGHT I’d well secured to another tree trunk. The bar clamp didn’t hold though and the boat “free fell” the last 2′. If I were to do this again I’d eliminate the bar clamp and wrap a towing strap around the ratchet side tree, like I did for the hand winch side.

Post flip with my comedic support crew.

Post flip, after lifting with car jacks and remounting the wheels to the frames.

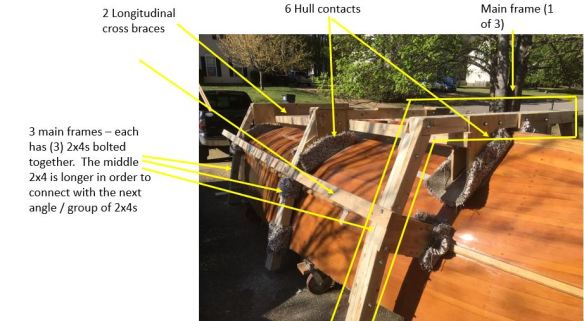

I built the flipping frame with the intent of converting it to a dolly. That meant that I needed to lift the frame and reattach the wheels. I’d considered doing this while the boat was mid-flip, which certainly would’ve been easier…but there would’ve been too much jostling and movement trying to get carriage bolts loose, redistributing weight, etc. It wouldn’t have been very safe. So I got the boat stable on the ground, lifted her up with car jacks and re-attached the wheels to two of the main frames.

Back to the barn

I’m pretty happy. Next step is to clean up the inside and deal with any gaps or plank beveling issues. Forward Progress.